Knowledge base

Agri-PV

Agri-photovoltaics, also known as Agro-PV or agricultural solar energy, is a way to combine agriculture with the production of renewable energy that is ready for the future. These two industries do not compete for land; they work together.

Challenges for AgriPV Investors – Foundation system

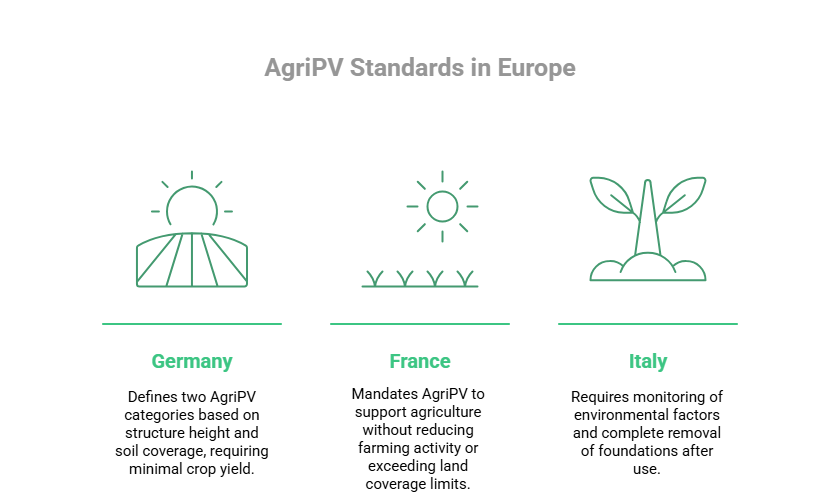

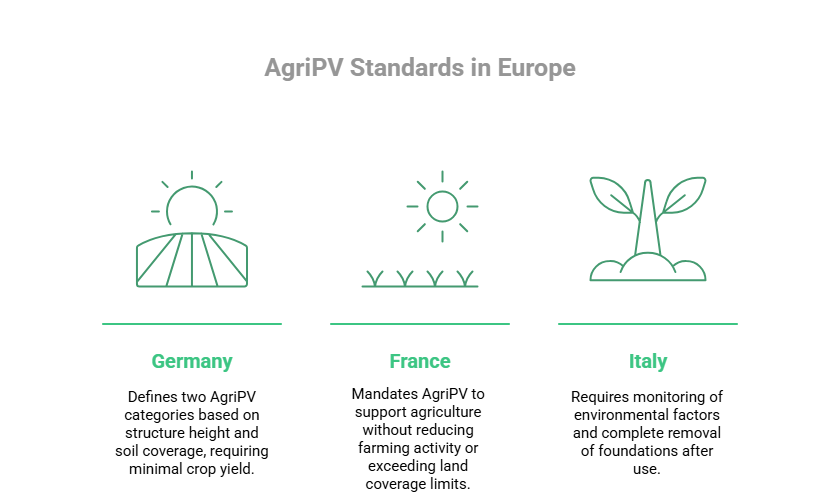

Across the EU, AgriPV systems are being regulated to ensure real synergy between solar energy production and agricultural activity. Let’s break down the main requirements from three key markets:

Germany: DIN SPEC 91434 divides AgriPV into two categories:

Category I: Elevated systems (≥2.1 m), with ≤10% of soil surface covered by foundations.

Category II: Lower systems, allowing up to 15% ground coverage.

A key point: at least two-thirds of normal agricultural yield must be preserved.

Soil protection is also essential – systems must be fully removable without leaving permanent impact.

The French Energy Code requires AgriPV systems to bring real benefits to agriculture – like improving crop conditions, climate adaptation, or water use.Projects that interfere with farming or take too much land are disqualified.

Italy adds rules about light permeability, soil fertility, and microclimate balance. Foundations must be fully removable and allow land to be restored after decommissioning.

And across all EU markets, there’s growing alignment with EN 62817, the technical standard for PV tracking systems – including mechanical performance, load resistance, and durability.

This is key for long-term AgriPV performance and compliance – and Winkelmann Foundation Screw meets this standard.

The broader European context

Currently, Germany is the only country with a highly detailed and technical AgriPV regulation – DIN SPEC 91434. It addresses crucial issues like soil health, land use limits, and the requirement to fully remove the foundations after the system’s life ends.

Other countries, like France, Italy, and Czechia, do have AgriPV guidelines, but these are more general – they lack the engineering specificity seen in the German norm. That’s why DIN SPEC 91434 is increasingly treated as a benchmark across the EU – and we will also use it as the reference standard in this presentation.

For investors, this creates a number of real-world challenges:

Soil protection is key – traditional concrete foundations can damage arable layers, affect drainage, and increase erosion risk.

Crop yields must be preserved – German law mandates minimum light and limits shading. If the microclimate under the modules is too harsh, crop output drops.

Removability is essential – especially in Italy, where the law requires full site restoration. Concrete makes this nearly impossible.

Installation time matters – concrete requires curing time (28 days), while screw piles can be installed and loaded immediately.

Projects must align with EU climate goals like REPowerEU – this includes lower emissions and circular construction.

And finally: cost and logistics. Concrete foundations are heavy, expensive to transport, and require more machinery, raising emissions and costs.

For all these reasons, steel screw foundations are becoming the optimal choice - combining speed, compliance, removability, and sustainability.

Comparison of foundation systems

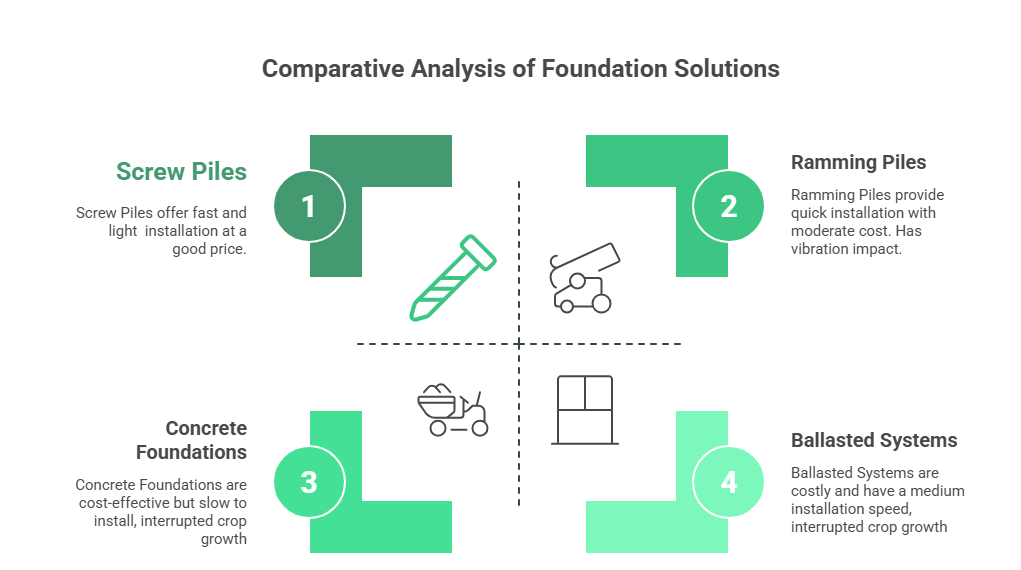

Let’s walk through the comparison of different foundation systems used in AgriPV projects, focusing on six critical criteria

Soil Protection: Screw piles are best-in-class here – they’re installed without excavation, cause minimal disturbance to the topsoil, and preserve the fertility of the land. Ramming piles are also effective but require heavy machinery, which can generate vibrations and compaction that may affect the soil. Concrete foundations perform the worst – they often compact or damage the soil structure and can disrupt water infiltration and root systems.

Removability: This is increasingly mandated by national laws – for example, Italy requires full reversibility of the installation. Screw piles and ramming piles are fully removable, leaving the site ready for agricultural reuse. Concrete, however, often leaves residual damage, and its removal is expensive and rarely complete.

Cost: While ramming piles and ballasted systems may have higher initial costs or require more site-specific engineering, screw piles remain cost-effective, especially when considering faster installation, lower transport needs, and easier logistics. Concrete foundations come with high costs due to curing time (28 days), heavy machinery, and transport of material.

EU Standards Compliance: Both screw piles and ramming piles comply well with frameworks like DIN SPEC 91434, which is the most detailed AgriPV regulation in Europe so far. These systems meet the requirements on soil protection, low surface impact, and removability. Concrete can only be justified under exceptional geological conditions and generally does not align with long-term environmental goals or reversibility requirements.

To align with today’s environmental, legal, and agricultural standards, reversible and low-impact solutions like screw piles are the best-fit foundation for AgriPV systems in Europe.

Winkelmann Foundation Screw

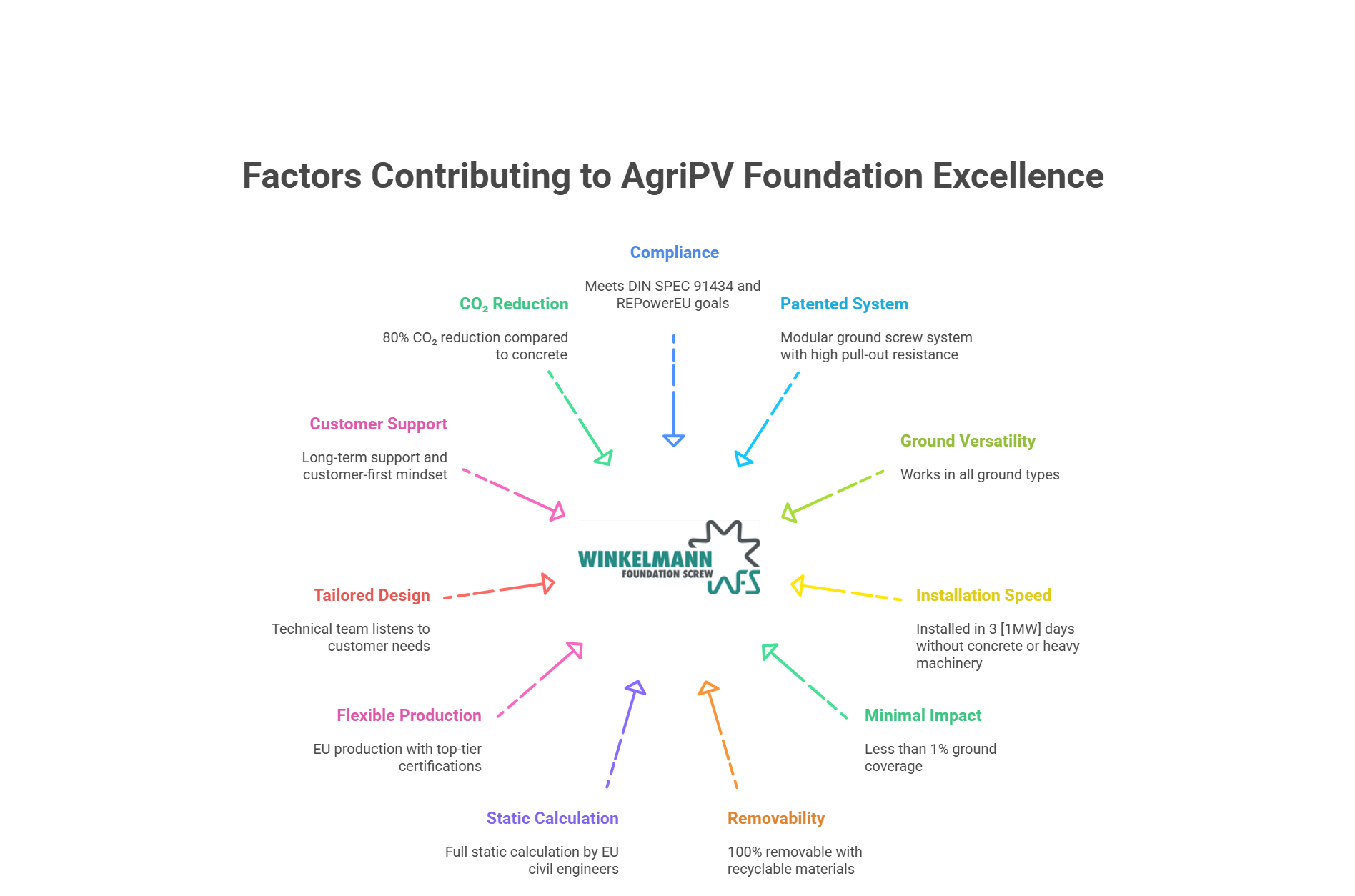

Winkelmann Foundation Screw is not just a screw pile. It’s a purpose-built, only available flow formed, fully certified AgriPV foundation system - designed in Europe, for European fields.

We comply with DIN SPEC 91434, protecting soil and securing agricultural yield.

We fulfill EN 62817, the strict European standard for PV tracker performance.

We meet the demands of regulators, farmers, and investors — all at once.

Our patented flange connection resists up to 250 kN of tensile force — perfect for static or tracking AgriPV.

And the system works everywhere — from soft fields to rocky terrain — without concrete, without excavation.

1 MW installed in just 3 days

Less than 1% land usage

80% less CO₂ than concrete

Full removal

Aligned with REPowerEU and ESG principles

But what really sets us apart?

We don’t just sell steel. We provide tailored, engineered solutions — backed by our EU-based production, certified static calculations, and a civil engineering team committed to one thing:

Your success.

So if you're ready to rethink what a foundation can do — we're ready to show you what Winkelmann Foundation Screw piles can do.

Let’s talk!

Do you have a project or a question?

Are you interested in our offer?