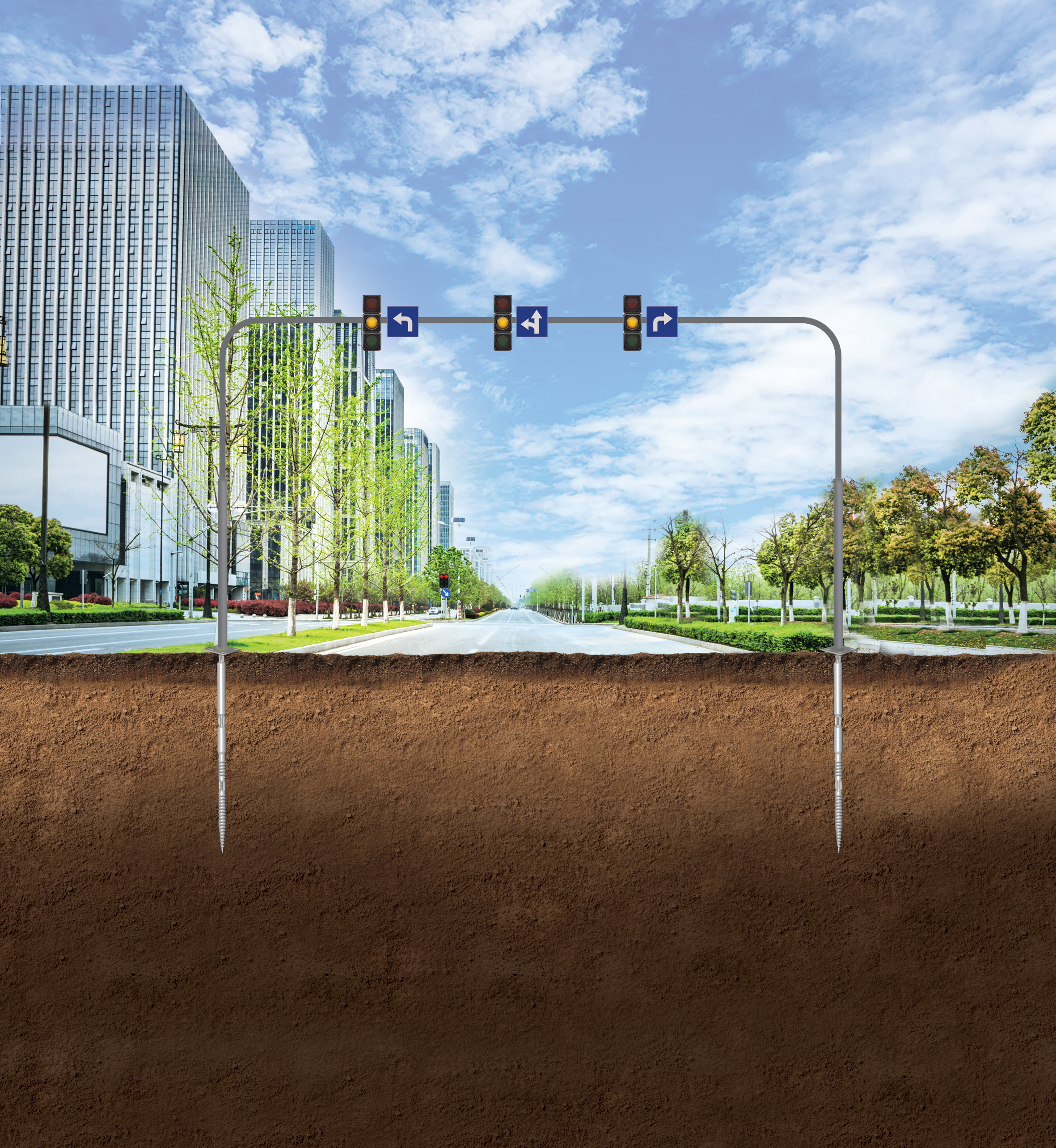

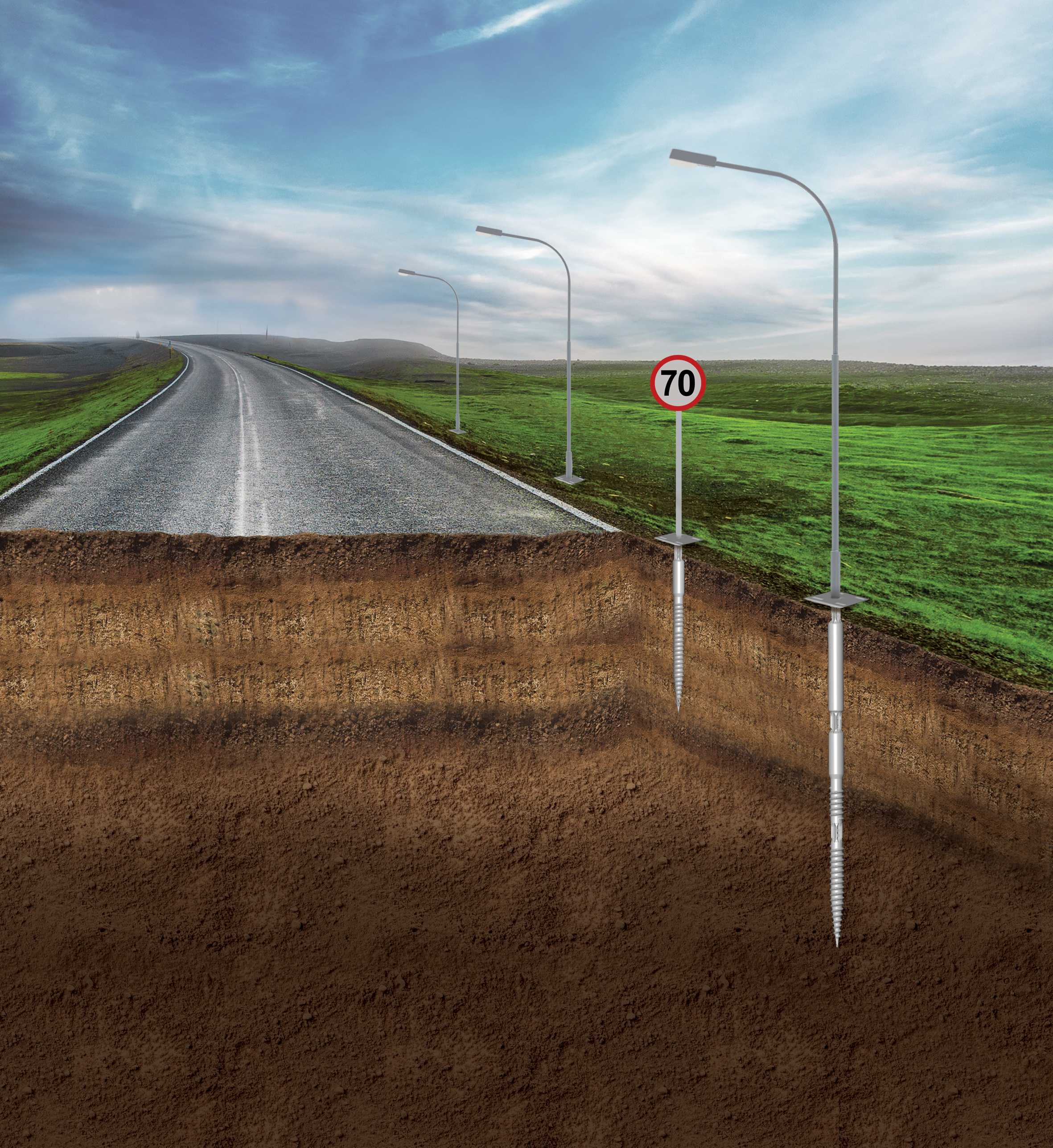

Areas of Application

Foundations for road infrastructure

If the foundation for road infrastructure is like a car’s gearbox, then foundation screw piles are undoubtedly the turbo mode. No concrete, no excavation, no investment delays – Winkelmann Foundation Screw (WFS) piles offer a technology that excels wherever time, load capacity, and minimal environmental impact are critical.

Building on a living organism

Road infrastructure projects – from national highways and urban intersections to park-and-ride lots and multimodal hubs – are like surgery on a beating heart. You can’t just stop traffic, redirect every user, or wait for concrete to cure.

That’s exactly why foundation screw piles are increasingly becoming the literal foundation for:

traffic signal masts,

variable message signs and information displays,

lighting columns,

overhead road structures (gantries, portals),

surveillance, ITS systems, and city cameras,

as well as crash barriers and acoustic screens.

These elements not only need to be installed rapidly – they must also remain functional for decades, regardless of wind loads, vibrations, or changing soil conditions.

A foundation that doesn’t cause disruption

Unlike traditional foundation methods, WFS screw piles:

require no excavation,

need no concrete,

are installed without interrupting traffic,

and become fully load-bearing immediately after installation.

Thanks to displacement foundation screw pile technology, the threaded shaft is driven directly into the ground – whether cohesive, non-cohesive, compacted, or loose. As a result, the piles don’t weaken the soil – they actually compact it, increasing overall bearing capacity.

Durability and precision in one solution

Constructed from high-grade structural steel and protected by hot-dip galvanizing, WFS foundations are resistant to:

road salt and de-icing chemicals,

fluctuating weather conditions,

mechanical damage,

and corrosion – even in high-humidity environments.

Each pile undergoes precise structural analysis – accounting for vertical and horizontal loads, as well as bending moments – making it a safe foundation even for the most demanding installations. The modular system allows the depth and configuration to be tailored to the specific requirements of each installation point.

For contractors: arrive efficiently, leave even faster

Time is money – and in road infrastructure, it’s also a key factor in safety and logistics. WFS screw piles allow you to:

complete installations within a single working day,

avoid weather-related delays,

minimize disruption to the environment and existing infrastructure (such as green verges or underground utilities),

and significantly reduce total foundation costs by eliminating wet works and heavy machinery.

And when a project requires relocation or decommissioning – the piles can simply be unscrewed and reused. Yes, this is a foundation that gives you a second chance.

The future of roads? Screwed in – not poured.

WFS proves that road infrastructure can be built quickly, precisely, and with environmental responsibility. Foundation screw piles are no longer an alternative – they are the new standard.

Thanks to their modularity, high load capacity, minimal invasiveness, and rapid installation, WFS foundations are perfectly suited to the realities of modern road construction – where there’s no room for error or delay.

No need to change direction. Just screw into the right technology.

Do you have a project or a question?

Are you interested in our offer?