Our services

Load Testing of Piles

A static load test of a pile is the most reliable method of assessing the bearing capacity of pile foundations. It is a field test that allows us to verify how the designed piles actually behave under load. The test provides precise information on whether a foundation pile will safely carry the expected loads and how it deforms under such conditions.

We offer our clients on-site static load testing of the designed screw foundation piles for a specific project, in accordance with the recommendations of the EN 22477 standard. We perform compression, tension, and horizontal load tests. Each load test takes approximately 5 hours.

When and why are load tests performed?

Load tests are recommended already at the design stage. They allow for the most accurate determination of bearing capacity, which enables the most economical foundation design. These tests also provide additional insight into ground conditions before the actual construction begins, which helps in better preparation, particularly in terms of installation planning.

Though they may seem like an unnecessary additional cost, in reality, they reduce the overall investment expense and eliminate design uncertainties.

What types of load tests are there?

A pile can be tested under any type of load it is expected to carry in service. The most commonly performed tests are compression (push-in) and tension (pull-out) tests, as these usually represent the dominant loads for such foundations. Lateral load tests are performed less frequently, since these loads tend to be low and are often insignificant for the pile's bearing capacity.

What is needed for the test?

First, the test must be properly designed, which requires both technical and specialized knowledge (e.g. based on the EN ISO 22477 standard or professional literature), as well as experience. It is necessary to determine, among other things, the design and location of the test pile and the types of loads to be applied. In general, geotechnical investigations, structural reaction forces, and a site layout plan are required.

Once the test is designed, work on the construction site can begin.

The following are necessary for conducting the load test:

Test pile (according to the project)

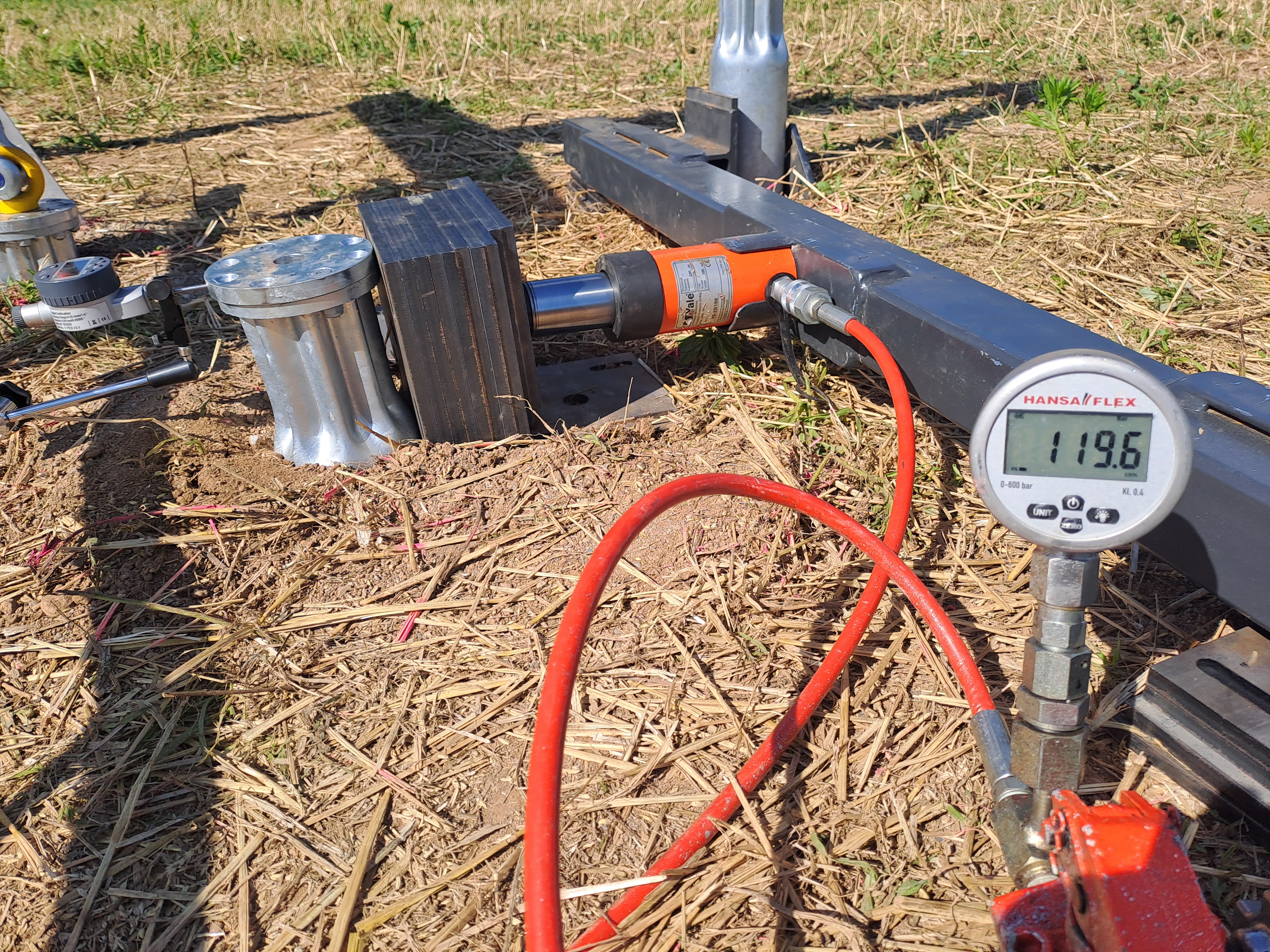

Reaction system (supporting piles, load-distributing beam or girder – “traverse” – with adequate capacity)

Loading system (hydraulic jack with appropriate pressure and stroke capacity)

Measuring system (displacement and pressure sensors – with appropriate measurement accuracy)

Test record sheet (for recording results and noting observations or comments)

How is the test prepared and conducted?

First, the test pile and the supporting piles are installed, along with the traverse beam. Then, a hydraulic jack is placed between the support structure and the test pile, connected to a pump and pressure gauge. Lastly, a displacement measuring system is installed in the direction of the applied force. After verifying the test setup and removing any slack in the system through preliminary loading, the test can begin.

During the load test, the pressure in the hydraulic jack is gradually increased or decreased in defined time intervals and cycles to reach the levels specified in the test sheet. At each stage, the current displacement is read and recorded using the dial gauge. Pressure readings are typically in bar, which, with knowledge of the cylinder area, can be directly converted into the force applied to the pile in kN. Displacements are measured in mm with appropriate precision.

The test is carried out until a required force, a limit displacement, or failure is reached. The required force is defined as the load which, after applying relevant correlation (statistical) and safety factors, still exceeds the design loads imposed on the structure. The limit vertical displacement is typically 10% of the pile diameter (e.g., 14 mm), while the acceptable horizontal displacement is determined based on the structure and client expectations (e.g., 30 mm for the pile head).

The test duration depends on factors such as soil conditions and the type and magnitude of the applied load. For WFS piles, the test should generally not exceed 6 hours.

What are the results and benefits of the test?

The main result of the test is a load-displacement curve ([kN] – [mm]), created based on the test data. This gives the designer real and valuable insight into the pile's behavior and bearing capacity. As a result, construction materials can be used more efficiently, and foundation costs can be optimized.

The tests are summarized in a detailed report, which thoroughly and precisely analyzes all the input and output data from the test.

Do you have a project or a question?

Are you interested in our offer?