Our technology

Flowforming

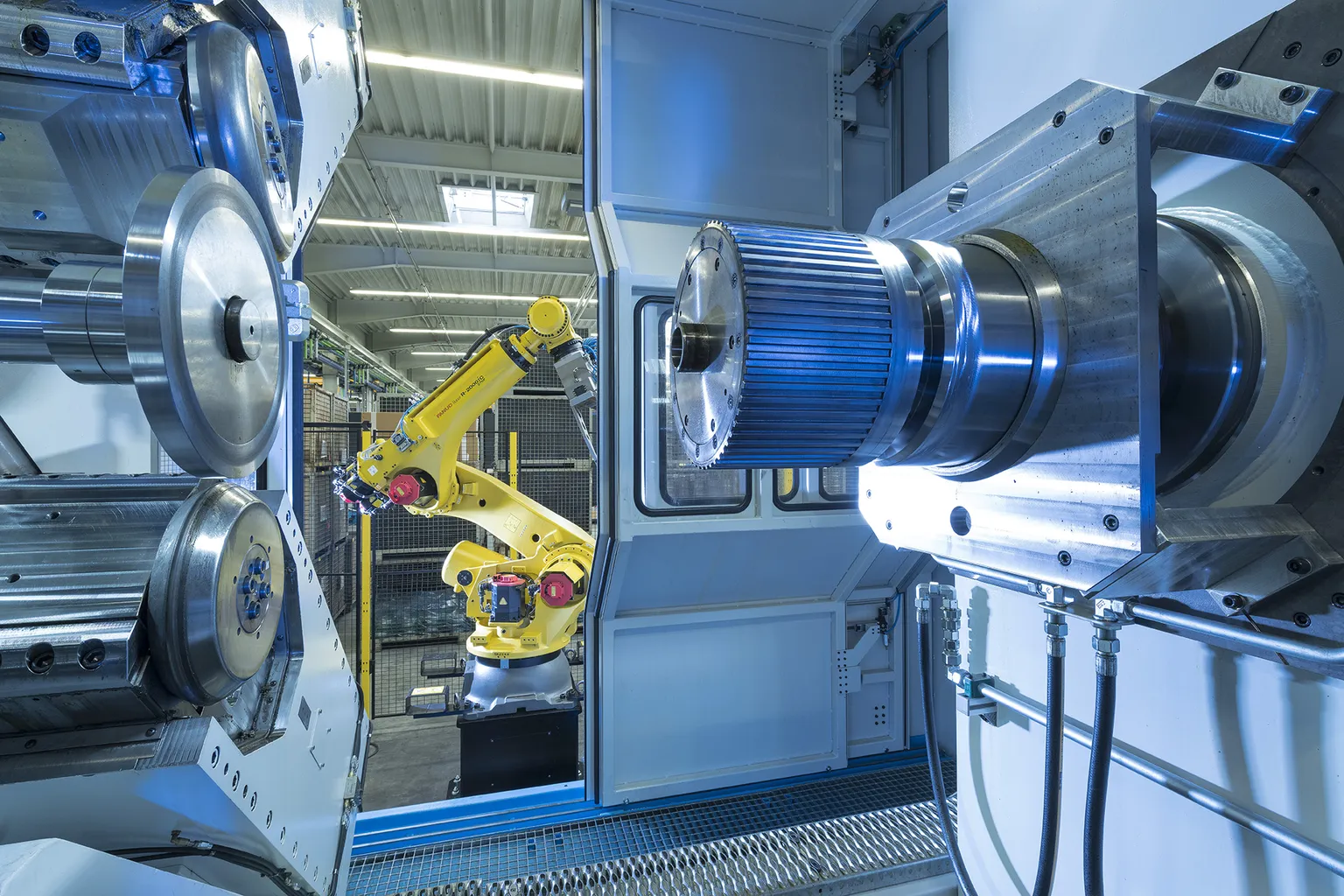

Flowforming technology, used by our company, is an advanced cold metal forming process employed for the precise shaping of cylindrical, rotational parts such as pressure vessels, drums, flanges, or covers. At the Winkelmann Group, this technology has been used for over 10 years in demanding applications within the aerospace, space, and defense industries.

Flowforming involves placing a preform (e.g. a disc or tube) onto a rotating mandrel, and then shaping it using one or several rollers that press the material against the mandrel. During this process, the material is axially elongated and stretched, taking on a highly precise shape.

This technology has been adapted for the processing of steel pipes, enabling us to manufacture foundation screws using a zero-waste method. The thread of our screws is hardened, while we simultaneously avoid the adverse effects associated with the traditional process of welding steel strips, such as heat impact, material discontinuities, and corrosion.

Do you have a project or a question?

Are you interested in our offer?