Areas of Application

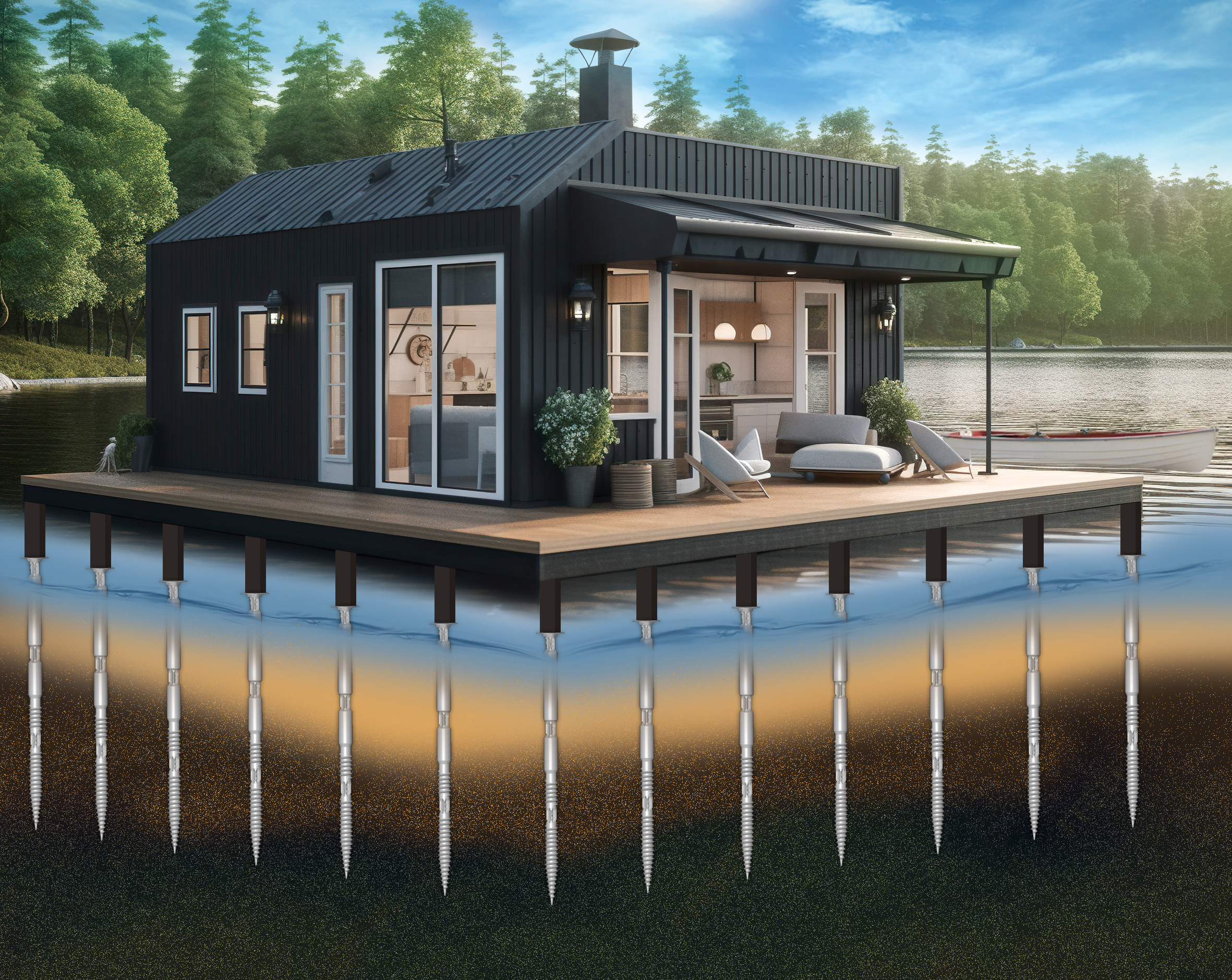

Foundations for modular homes

A foundation is the key element ensuring safety, durability, and fast project completion in the increasingly popular single- and multi-story modular and container construction.

The lifespan and functionality of the entire structure depend on the chosen foundation system – whether it’s for an energy storage system (BESS), an office container, or a shipping container.

Wide application of containers and modular buildings

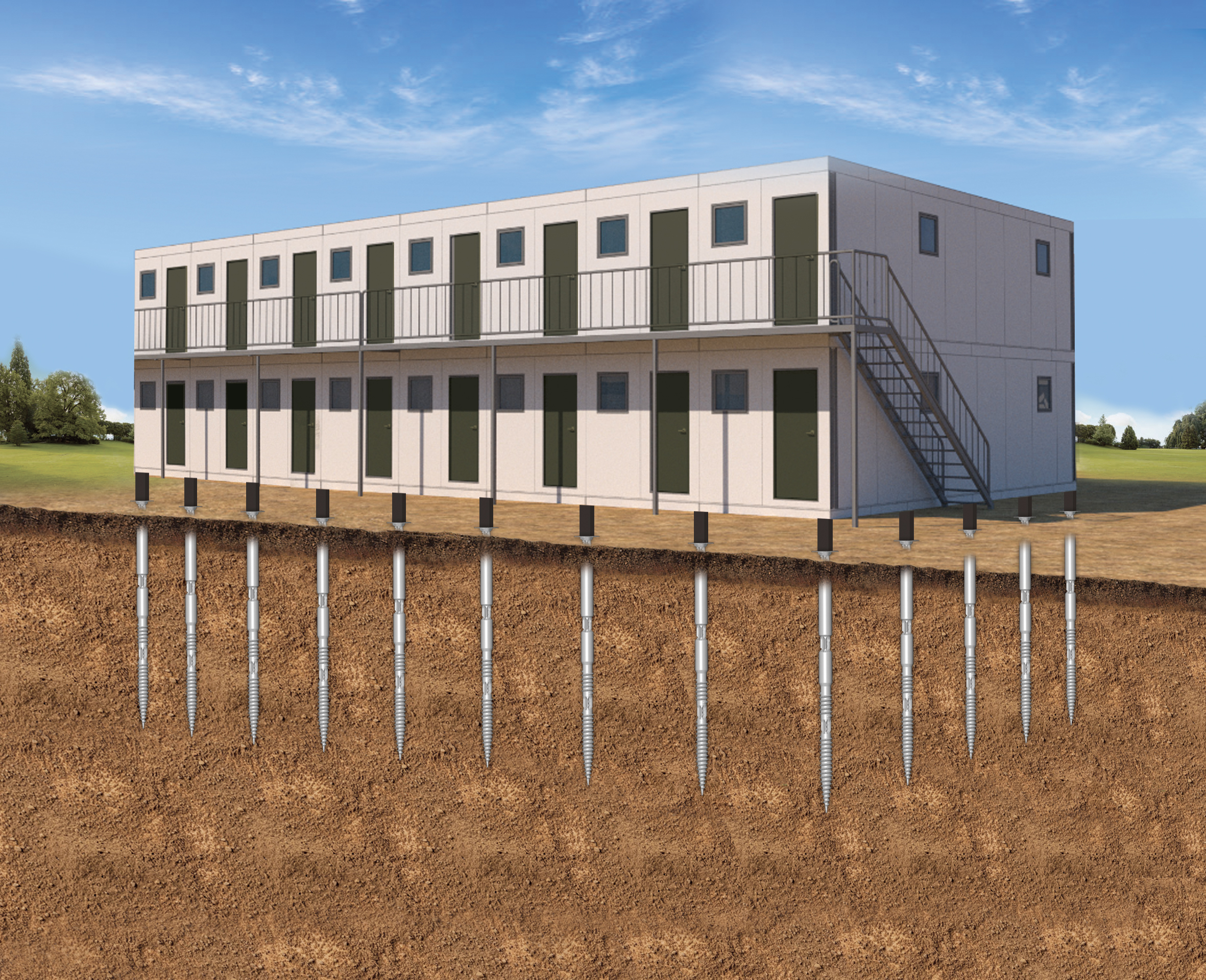

Today, container structures are used across many industries – as schools, hospitals, offices, apartments, modular homes, and technical facilities such as boiler rooms, biomass containers, or energy storage units. Containers can be made of steel or prefabricated materials, and their foundations must match the soil conditions and load requirements.

Simple technical structures like tool sheds or construction site facilities usually don’t require complex foundations. However, for buildings used by people or designed for energy storage, the foundation must be solid, precisely engineered, and capable of handling long-term loads.

Comparing container foundations: Which technology to choose?

The most commonly used foundations for containers include screw piles (ground screws), cast-in-place concrete, and precast concrete elements. When planning a project, it’s important to consider the advantages and limitations of each system.

Precast concrete elements are a fast and low-cost solution, particularly suitable for lightweight and temporary structures. They require no specialized equipment and are widely available. However, their load-bearing capacity is limited, and the lack of permanent bonding with the soil can lead to uneven settling – especially in multi-story constructions or weak soil conditions.

Cast-in-place concrete foundations offer excellent durability and design flexibility. They are effective for heavy loads and permanent structures. However, they are time-consuming to install, weather-dependent, emit CO₂, and require heavy equipment and extensive earthworks – significantly extending the project timeline.

Screw pile foundations – also known as ground screws – are a modern and flexible solution. The Winkelmann Foundation Screw system eliminates the need for concrete and allows for installation in any weather, using light machinery to screw the steel piles into the ground.

This creates a foundation ready for immediate load – ideal for both lightweight temporary structures and heavy container systems, where durability, resistance to dynamic loads, and user safety are crucial.

Additionally, the cold-formed screw piles are corrosion-resistant thanks to special coatings, and the entire system can be dismantled and reused – a sustainable and environmentally friendly solution.

Winkelmann Foundation Screw – Fast and eco-friendly screw pile foundations

Our screw foundations are locally produced, certified according to European standards (e.g., abZ DIBt), and designed by experienced civil engineers licensed throughout the EU. We offer a wide range of solutions – from single foundation screws for small buildings to advanced systems for multi-story containers and energy storage facilities.

If you're looking for a fast, durable, and ecological foundation for an office container, modular house, energy storage system, or any other temporary structure – the Winkelmann Foundation Screw team is ready to advise and support your project every step of the way.

Start your project with a solid foundation – contact us today!

Do you have a project or a question?

Are you interested in our offer?